Arm Protection—The Forgotten Hazard

When PPE planning stops at gloves, safety gaps emerge. These gaps can lead to preventable injuries—even in roles where incidental arm contact with hazards is highly likely. Despite clear risks, protective sleeves remain one of the most underutilized PPE components on the jobsite. Gloves are typically non-negotiable, but sleeves are often treated as optional. This oversight can result in lacerations, burns, or other injuries that are otherwise easily avoidable with arm coverage that complements and extends the protection offered by gloves.

How protective sleeves fit within a holistic hand safety program

Effective safety strategies consider the full body—not just individual PPE components in isolation. Sleeves play a vital role in this larger ecosystem by bridging the gap between gloves and torso protection.

In industries like metal fabrication, HVAC, oil and gas, and manufacturing, arm exposure to sharp or hot surfaces is routine. Even the most advanced glove designs cannot protect the forearm. Sleeves are the missing link that close this vulnerability.

Beyond gloves and sleeves, a well-rounded PPE approach includes other protective PPE such as safety apparel, headwear, goggles, and other task-specific gear. When these elements work together, they create a comprehensive defense against workplace hazards.

Comfort is key to compliance

Even the most advanced PPE is ineffective if workers choose not to wear it. That’s why comfort is a cornerstone of compliance—and protective sleeves are no exception.

Modern sleeves are now engineered with materials that balance durability, dexterity, and breathability. When workers feel unrestricted and comfortable, they’re far more likely to wear PPE consistently and correctly.

Superior Glove recognizes this and has developed a range of protective sleeves that prioritize comfort while delivering industry-leading protection. Whether it’s high cut, heat, or flame resistance, the focus remains on combining safety with wearability for all-day wear.

Understanding Sleeve Designs and Material Technologies

Protective sleeves are not one-size-fits-all. Different jobs call for different sleeve fits, materials, and protective properties. Superior Glove offers multiple configurations to meet diverse industry needs.Sleeve style and fit:

Tubular Fit: Slightly looser, providing general protection with enhanced airflow and comfort.

Tapered Fit: Slimmer, closer-fitting design for better dexterity, reduced snagging, and ease of movement.

Material options and applications:

TenActiv™: Breathable and lightweight with excellent cut resistance—ideal for precision work with sharp components.

ParaActiv™: Naturally flame-resistant, suited for high-heat tasks.

Wirecore: Reinforced with steel fibers for environments requiring maximum cut protection.

Polyester / Nylon Blends: Flexible and abrasion-resistant for general-purpose applications.

FR Modacrylic / Wool: Provides long-term heat and flame resistance for extended exposures.

Key Sectors That Benefit from Arm Protection

While sleeves benefit a wide range of sectors, they are especially critical in the following industries:

Metal Fabrication & Welding: Defends against sparks, sharp metal edges, and high temperatures.

HVAC & Construction: Protects from cuts and abrasions during installations in confined areas.

Oil & Gas Maintenance: Shields arms from burns and cuts while navigating tight, hazardous environments.

Automotive Assembly: Prevents lacerations during work with metal frames and sharp components.

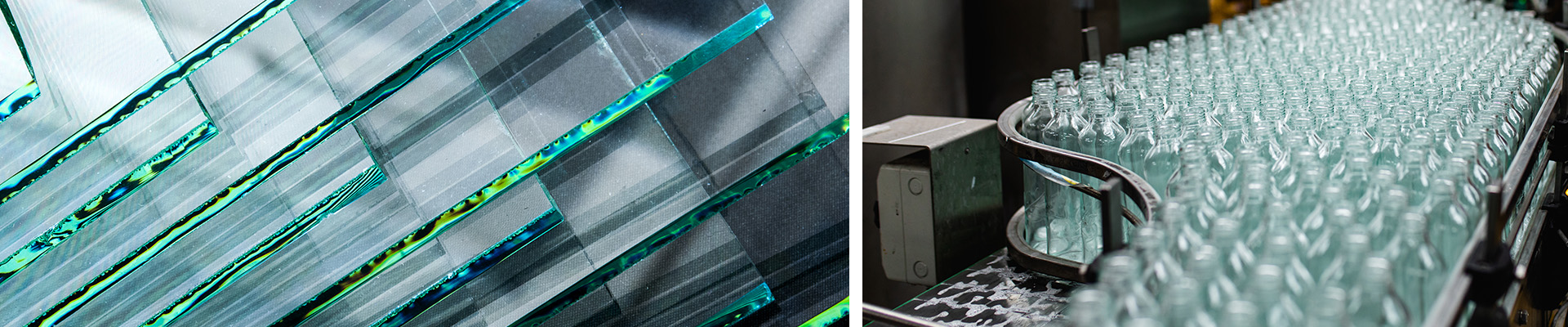

Glass Manufacturing: Reduces risk of serious cuts when handling panes and shards.

Food Processing: Adds a layer of hygiene while helping to avoid cross-contamination.

Strengthening safety by closing the gaps

A truly effective PPE program is one that sees the body as an interconnected system. Gloves protect hands, sleeves shield arms, and garments safeguard the torso and legs. When any part is neglected, the entire system is compromised.

By prioritizing arm protection and integrating sleeves as standard PPE—not optional—safety managers can help reduce workplace injuries, improve compliance, and foster a culture where comprehensive protection is the norm. With the right sleeves, safety doesn’t come at the cost of comfort or productivity.

Would you like to learn more about safety gloves and hand protection? Click through to read ‘How to choose cut resistant gloves.

Book a complimentary glove review

Levitt-Safety offers complimentary glove reviews

to examine your onsite hazards and PPE requirements. We’ll bring a skilled glove expert to your facility to review your hand protection program, identify workplace hazards, and provide suggestions for areas of improvement. Fill out a form to get started